Showing 577–608 of 2724 results

-

Mini Mandrils & Accesries

Cut Off Discs 22 x 0.25mm 5 Pieces

Quick ViewR165,00The cutting discs can be used to cut grooves in glass or to make delicate cuts in metals, wood and plastic.

Use mandrel M8110 with the cutting discs.

Please keep in mind that the cutting discs are not reinforced.

QTY: 5

-

Mini Mandrils & Accesries

Cut Off Discs 22 x 0.6mm 10 Pieces

Quick ViewR120,00The cutting discs can be used to cut grooves in bolts or screws or to make delicate cuts in metals, wood and plastic.

Use mandrel M8110 with the cutting discs.

Please keep in mind that the cutting discs are not reinforced.

QTY: 10

-

Mini Mandrils & Accesries

Cut Off Discs 22 x 0.6mm 50 Pieces

Quick ViewR520,00- The cutting discs can be used to cut grooves in bolts or screws or to make delicate cuts in metals, wood and plastic.

- Allows for compact and accurate cutting/sawing

- Fits standard collets

- The PG Mini range combines utmost precision with the convenience of universal tools and guaranteed strength

-

Mini Mandrils & Accesries

Cutt Off Discs 40 x 1mm Reinforced 5 Piece

Quick ViewR105,00M5050 - The cutting discs can be used to cut grooves in bolts or screws or to make delicate cuts in metals, wood and plastic. -

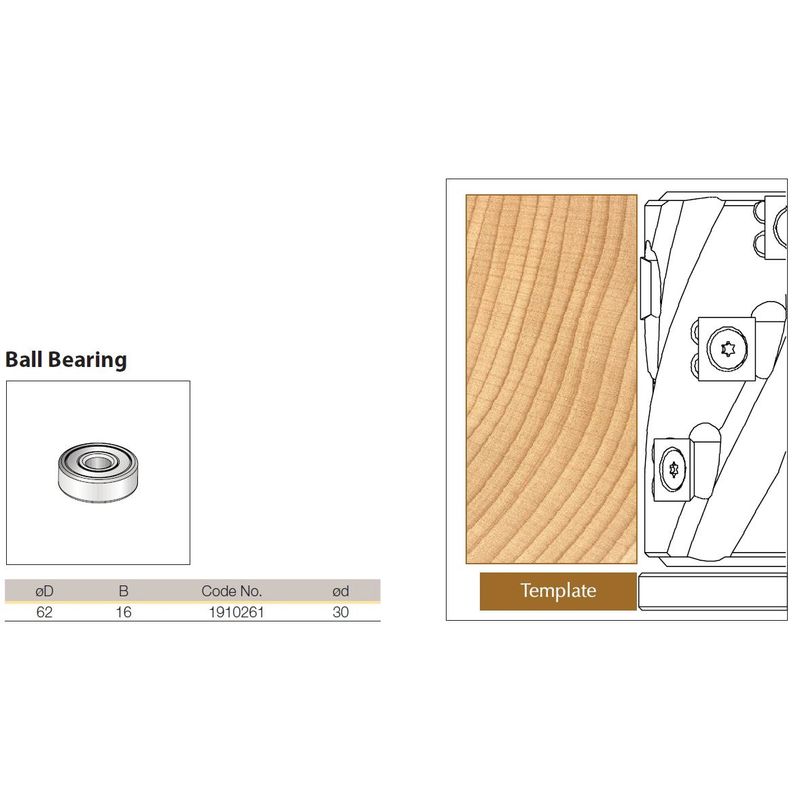

Cutting

Cutter Block, Bearing 62mm x 30mm

Quick ViewR200,00R390,001910261 - Cutter Block, Bearing 62mm x 30mm -

Annular Or Broach Cutters

Cutter HSS – M2, 12 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR340,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 12 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR420,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 14 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR320,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 14 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR400,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 16 x 25mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR350,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 18 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR360,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 18 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR510,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 20 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR400,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 20 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR530,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 22 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR450,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 22 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR570,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 24 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR660,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 26 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR560,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 26 x 55mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR700,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter HSS – M2, 32 x 30mm, Annular Or Broach Cutter Slugger Bit

Quick ViewR700,00- One way to avoid dimpling and deburring while making holes in tube and pipe is to use annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone resistance to overcome.

- Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

- The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called "dead zone." This dead zone causes the surface speed of the cutting edges to drop to zero.

- The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

- Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

- Annular cutters convert a smaller area to chips, requiring less horsepower and thrust. This feature provides longer tool life and less chatter. The slug also offers a higher scrap value than loose chips and shavings.

-

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

-

Annular Or Broach Cutters

Cutter Pilot Pin, Long – 102mm For Annular Or Broach Cutter

Quick ViewR50,00-

Pilot pin with length of 102 mm specifically for annular cutters (broach cutters) with a cutting length of 55 mm.

-

-

Annular Or Broach Cutters

Cutter Pilot Pin, Short – 79mm For Annular Or Broach Cutter

Quick ViewR47,00- Pilot pin with length of 102 mm specifically for annular cutters (broach cutters) with a cutting length of 55 mm.

-

Mini Kits

Cutting Accessory Kit – 58 Piece

Quick ViewR840,00Accessories kit for cutting of small applications -

Angle Grinder Accessories

Cutting Stand For Angle Grinders, EINHELL TS230mm

Quick ViewR1250,00Description:

Einhell TS 230 Cutting Stand for 230mm Angle Grinders